Yo

1

/

of

2

Tapping chucks for synchronisation HSK 100 - M3-M12 - 100 | ER 16

Tapping chucks for synchronisation HSK 100 - M3-M12 - 100 | ER 16

Regular price

€378.00

Sale price

€378.00

Regular price

Unit price

/

per

Tax included.

Shipping calculated at checkout.

Product Details

Application:

For machining centres with synchronous spindle.

Note:

- Synchro tapping chucks compensate synchronisation errors.

- Minimal length compensation on compression and expansion balances very small pitch differences between synchro spindle and tap, which can cause high frictional forces on the thread flanks.

- A possible increase of axial force during the tapping process is reduced to a minimum.

- Suitable for internal coolant.

- Coolant pressure up to max. 100 bar.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm² after DIN

- All functional surfaces fine machined

| Property | Specification |

|---|---|

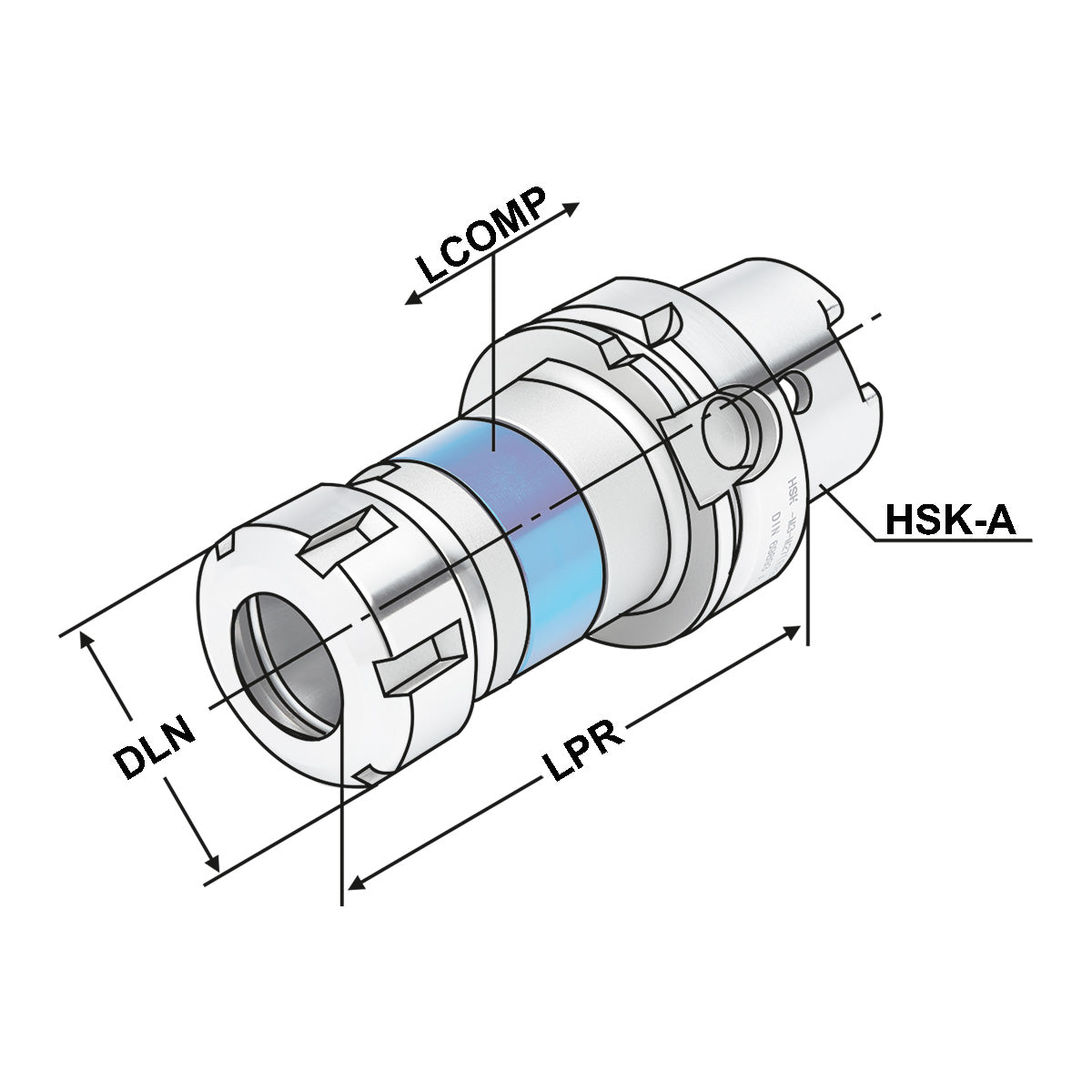

| Typ | 426E | ER 16 | SW25 |

| ADINTMS | ISO 12164 (HSK-A) |

| ADINTWS | ISO 15488 Gewindeschneidfutter |

| DLN | 28 |

| LPR | 96 |

| LCOMP | 0,5 |

| Auswuchtgüte | G6,3 | 15.000 1/min |

| DCP | Ja |

| DCPS | D10/H4,5 |

| HSK | HSK-A 100 |

| max. Rundlaufabweichung | < 60µm |

Expected delivery date:

19 Dec

Usually ready in 6-7 days.

Couldn't load pickup availability

Tapping chucks for synchronisation HSK 100 - M3-M12 - 100 | ER 16

Regular price

€378.00

Sale price

€378.00

Regular price

Unit price

/

per

Tapping chucks for synchronisation HSK 100 - M3-M12 - 100 | ER 16

Regular price

€378.00

Sale price

€378.00

Regular price

Unit price

/

per

Product description

Application:

For machining centres with synchronous spindle.

Note:

- Synchro tapping chucks compensate synchronisation errors.

- Minimal length compensation on compression and expansion balances very small pitch differences between synchro spindle and tap, which can cause high frictional forces on the thread flanks.

- A possible increase of axial force during the tapping process is reduced to a minimum.

- Suitable for internal coolant.

- Coolant pressure up to max. 100 bar.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm² after DIN

- All functional surfaces fine machined

Material

N/A

Year

N/A

Features

N/A

Dimensions

N/A