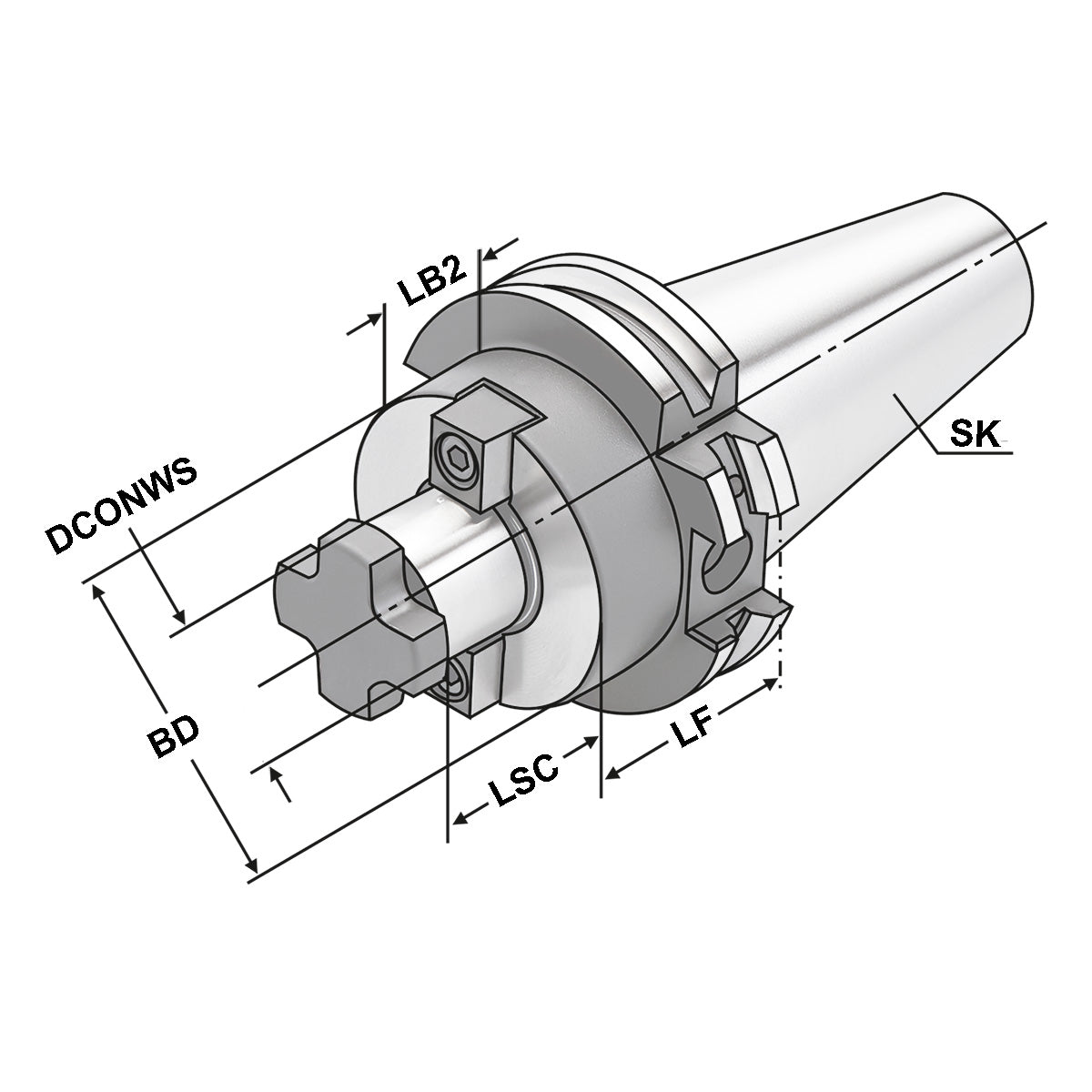

Shell mill holder SK 40 - 40 - 160

Shell mill holder SK 40 - 40 - 160

Application:

For mounting milling cutters with transversal groove.

Note:

d = 40/d = 60: For large diameter face mill cutters with four additional threaded holes according to DIN 2079.

SK 30 without coolant exit bores on the end face

Delivery:

With drivers, cross head retaining screw and cylinder head retaining screw for cutters with central coolant. For d = 60 only with four fi xation screws according to DIN 912.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm² after DIN

- All functional surfaces fine machined

| Property | Specification |

|---|---|

| DCONWS | 40 |

| BD | 88 |

| ADINTMS | ISO 7388-1 (DIN 69871) |

| ADINTWS | DIN 6357 (Quernut) |

| LSC | 27 |

| Rundlauf | < 5µm |

| TDCON | h6 |

| LF | 160 |

| CNSC | AD/AF (AD/B) |

| SK | SK 40 |

| Auswuchtgüte | G2,5 | 25.000 1/min |

| DCP | Ja |

| DCPS | D10/H4,5 |

| CXSC | Kühlkanäle |

| LB2 | 140,9 |

Couldn't load pickup availability

Shell mill holder SK 40 - 40 - 160

Shell mill holder SK 40 - 40 - 160

Application:

For mounting milling cutters with transversal groove.

Note:

d = 40/d = 60: For large diameter face mill cutters with four additional threaded holes according to DIN 2079.

SK 30 without coolant exit bores on the end face

Delivery:

With drivers, cross head retaining screw and cylinder head retaining screw for cutters with central coolant. For d = 60 only with four fi xation screws according to DIN 912.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm² after DIN

- All functional surfaces fine machined